AVR projects

Pilot: from CO₂ and fly ash to a new raw material

AVR and British company Carbon8 are working together on a pilot trial in which captured CO₂ is combined with fly ash to create a kind of gravel that is new raw material for the construction sector. The magical conversion process is taking place in the pilot installation, the so-called ‘CO2ntainer’, at our facility in Duiven. After an initial test phase we are now striving for a successful up scaling of the process. Towards this end, our residual flows of both CO₂ and fly ash are now put to good use rather than being emitted or dumped.

Supplying steam to neighbouring company 4PET

From 2021 AVR Duiven will supply steam as well as electricity to recycling company 4PET. The contract for this supply has been signed by both companies. Until now 4PET has used a propane gas-fuelled plant to produce the heat needed for its production process. AVR’s steam offers 4PET a sustainable alternative. Installing the direct steam connection involved a number of activities, such as the construction and installation of a pipe bridge and the steam and condensate pipelines. In the final phase the instrumentation will be connected and the pipes insulated.

CO₂ as a fuel in the greenhouse horticulture sector

Since August 2019 one of the largest CO₂ capture plants in Europe waste sector has been in operation in Duiven. The CO₂ released by AVR after residual waste is incinerated is serving as a key raw ingredient for growing crops. The around 60,000 tons of captured CO₂ we can supply the growers each year means they no longer have to use gas-fired installations to produce the CO₂ they need. Building a similar CO₂ capture plant in Rozenburg is high on our agenda.

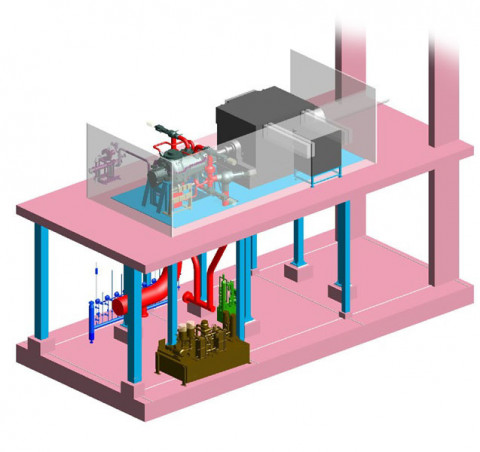

A new steam turbine for more energy

In 2020-2021 a new turbine configuration will be installed in the AVR Rozenburg power plant. The new Siemens back pressure turbine – the so-called ‘Turbine F’ – will replace the old, outdated turbine. This will enable us to meet the anticipated demand for district heat and process steam. At maximum power the new turbine can provide the annual electricity requirements of 60,000 households and, at the same time, supply heat to 100,000 households. This investment will enable AVR to extract even more energy from the residual waste and, as a result, reduce its CO₂ footprint.